Welding ace

turbocad v 15 2d 3d design software.

Saturday, 15 October 2011

PageRage: Welcome to the unofficial pagerage blog

PageRage: Welcome to the unofficial pagerage blog: Pagerage is a quick and free way to create great looking facebook pages. The software is free but is supported by adverts. You can choose ...

Thursday, 14 July 2011

The Bulldog shear in action.

Well I do not just design them I drive them too. This is in South Wales a few year ago. On the footplate is my old faithful English Bull terrier Benji and what a smart sucker he was too. We soon learned that a splash of oil on the teeth mad a dramatic difference to it's performance.

The open ended design meant that they were prone to operator abuse. But a good operator could get through a lot of metals in a day.

The open ended design meant that they were prone to operator abuse. But a good operator could get through a lot of metals in a day.

Sunday, 19 June 2011

Rising costs.

Metal prices are at a very high premium indeed at the moment and if you are manufacturing anything at all you be looking at using the very latest technology.

I have more or less come to the opinion that the UK and others have decided to sit back and tax us out of the recession. Why ?

Well we now compete on a global scale and If you can make some thing elsewhere and ship it to the uk that is what will happen.

A government employee I spoke to last week told me that people will not always go for the cheapest option.

When I pointed out that some of these cheaper options are coming with lifetime guarantees I was met with a stony silence.

Working conditions in the emerging economies are not going to be the same as in the west.

I touched on this a few years ago when the current glut of degree holders were being unleashed on the jobs market.

No one was listening then and are probably not now.

Most university graduates I know are making sandwiches at Subway or flicking Burgers at Mc Donalds.

I do feel genuinely sorry for a lot of them because they really did think they were being prepared for a new world where there skills in Social Sciences were needed.

I am afraid not.

What,s the good news. Well you must of shown aptitude for learning something.

I have more or less come to the opinion that the UK and others have decided to sit back and tax us out of the recession. Why ?

Well we now compete on a global scale and If you can make some thing elsewhere and ship it to the uk that is what will happen.

A government employee I spoke to last week told me that people will not always go for the cheapest option.

When I pointed out that some of these cheaper options are coming with lifetime guarantees I was met with a stony silence.

Working conditions in the emerging economies are not going to be the same as in the west.

I touched on this a few years ago when the current glut of degree holders were being unleashed on the jobs market.

No one was listening then and are probably not now.

Most university graduates I know are making sandwiches at Subway or flicking Burgers at Mc Donalds.

I do feel genuinely sorry for a lot of them because they really did think they were being prepared for a new world where there skills in Social Sciences were needed.

I am afraid not.

What,s the good news. Well you must of shown aptitude for learning something.

Thursday, 2 June 2011

A competitive edge

Well it is time I explained why I started doing all the typing. Because I have always had my feet in two camps, Demolition and Demolition equipment manufacture. Metal prices for most of my life have remained pretty stable except in recessions. Scrap metal prices have gone through the roof in the last few years and are currently at about £250 per tonne. Now that is only the start of it as the scrap metals then have to be processed melted down rolled etc.

So it stands to reason if you are going to manufacture anything at all you need a competitive edge.

That is where the computer comes in and a bit of kit called a cad program.

Once done in cad you have it forever, make sure you back it up of course.

We use a magic eye profile cutter so once the drawing is printed off it is just a matter of placing the drawing on the table for the machine to follow.

What is the down side then. Well I found it very hard to learn but I was used to doing things the old school way.

If you have been doing some thing one way it is very hard to change .

Implementing new technology whilst running a busy shop Is just not going to happen. Why did I do it.

Well an old mate and brilliant engineer Mike Reynolds died a few years ago virtually penniless and that is hard fact to swallow.

He would never embrace new technology and would not know how to turn a computer on.

Many can not see what learning fairly complex software would do for them but believe me it is worth the effort.

You can sit back easy now as I do not sell any type of cad program but there is loads out there and nearly all offer free trials.

So if you would rather sit and watch tv ok fine but you have been warned.

On bbc tv last week was a leading business man saying that we do not have enough cad and cam engineers. Well I do not need telling twice.

So it stands to reason if you are going to manufacture anything at all you need a competitive edge.

That is where the computer comes in and a bit of kit called a cad program.

Once done in cad you have it forever, make sure you back it up of course.

We use a magic eye profile cutter so once the drawing is printed off it is just a matter of placing the drawing on the table for the machine to follow.

What is the down side then. Well I found it very hard to learn but I was used to doing things the old school way.

If you have been doing some thing one way it is very hard to change .

Implementing new technology whilst running a busy shop Is just not going to happen. Why did I do it.

Well an old mate and brilliant engineer Mike Reynolds died a few years ago virtually penniless and that is hard fact to swallow.

He would never embrace new technology and would not know how to turn a computer on.

Many can not see what learning fairly complex software would do for them but believe me it is worth the effort.

You can sit back easy now as I do not sell any type of cad program but there is loads out there and nearly all offer free trials.

So if you would rather sit and watch tv ok fine but you have been warned.

On bbc tv last week was a leading business man saying that we do not have enough cad and cam engineers. Well I do not need telling twice.

Tuesday, 17 May 2011

Designed by computers

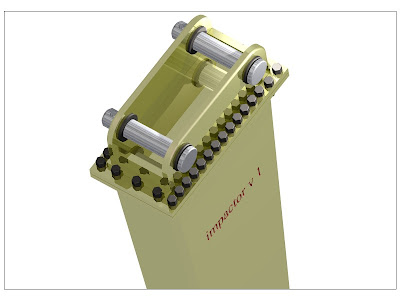

The following picture is of the con rod and bracket assembled.

The parts are designed by computer with turbocad design software.

The parts can be assembled "virtually" and it is possible to see where the various parts will fit.

Animation is also possible to check for ram stroke and clearances.

Of course this takes slightly longer than how we used to work with paper drawings, But after the initial outlay in extra hours we end up with a design that we can use time and time again with no extra cost.

Very clever INNIT !!!

The parts are designed by computer with turbocad design software.

The parts can be assembled "virtually" and it is possible to see where the various parts will fit.

Animation is also possible to check for ram stroke and clearances.

Of course this takes slightly longer than how we used to work with paper drawings, But after the initial outlay in extra hours we end up with a design that we can use time and time again with no extra cost.

Very clever INNIT !!!

very versatile

The addition of a con rod bracket to your dipper arm of the excavator is the only fixed item you need. After fitting the bracket a vast number of attachments can be employed from grabs to concrete puverizors. Watch out for our new design of an attachment for dealing with light iron

Subscribe to:

Posts (Atom)